Brass Check Valve - China Manufacturers, Factory, Suppliers

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Brass Check Valve, Vertical Non Return Valve, Dual Pilot Operated Check Valve, Ball Type Foot Valve,Brass Swing Check Valve. We have expanded our business into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of the world. We are working hard to be one of the best global suppliers. The product will supply to all over the world, such as Europe, America, Australia,Pakistan, Iraq,Malta, Bulgaria.As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

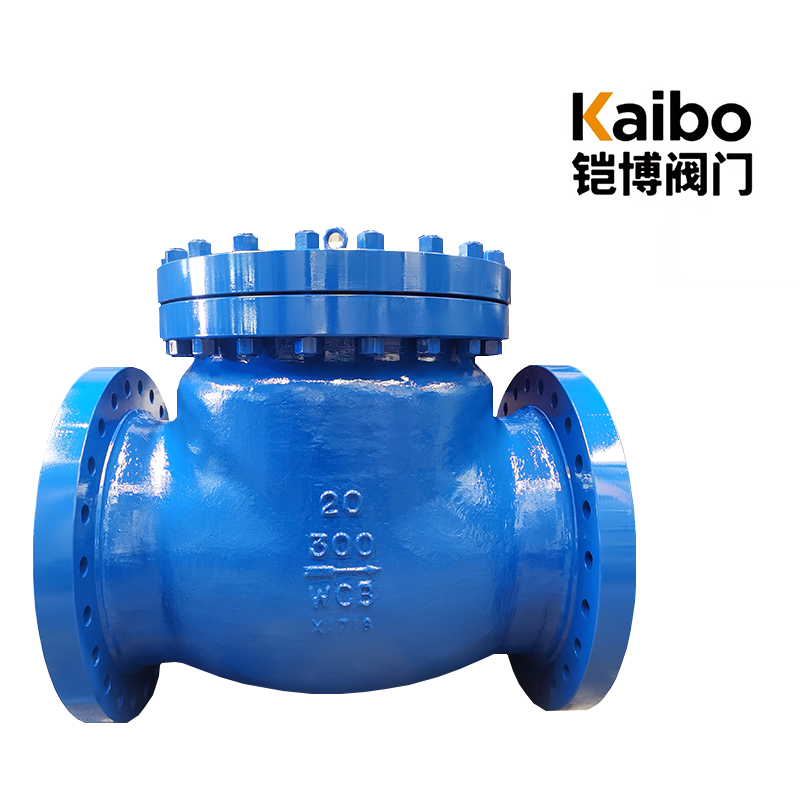

Related Products