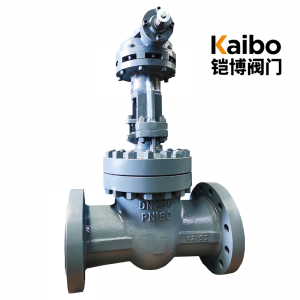

Bevel Gear Gate Valve

The gate valve is suitable for a wide range of pressure, temperature and diameter, especially for medium and large diameter pipelines.

From the simplest American standard gate valve to various American Standard valves used in extremely complex automatic control systems, there are quite a wide variety of varieties and specifications. This valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media.

1. The product is designed and manufactured according to API standards, with reliable sealing and excellent performance, and can be used together with imported equipment.

2. The gate and valve seat seal above 600Lb are made of Stellite cobalt based cemented carbide, with wear resistance, high temperature resistance, corrosion resistance, good scratch resistance and long service life

3. The valve stem is subject to quenching and tempering and surface nitriding treatment, which has good corrosion resistance and scratch resistance.

4. Wedge type elastic ram structure is adopted, medium and large diameter rolling bearings are set, and the opening and closing is easy.

5. The valve body has a complete variety of materials, and the packing and gasket are reasonably selected according to the actual working conditions or user requirements, which can be applicable to various pressure, temperature and medium working conditions.

6. 1500Lb and 2500lb middle cavities adopt pressure self tightening sealing structure. The sealing performance increases with the increase of internal pressure and has high reliability.

7. The inverted seal is made of stainless steel threaded connection seal seat or austenitic stainless steel surfacing on the body. The inverted seal is reliable. The filler replacement and maintenance can be carried out without shutdown, which is convenient and fast without affecting the operation of the system.

| DN | 150LbRF | ||||||||

| mm | in | L | D | D1 | D2 | b | Z-φd | H | D0 |

| 15 | 1/2 | 108 | 89 | 60.5 | 35 | 11.5 | 4-φ16 | 165 | 100 |

| 20 | 3/4 | 117 | 98 | 70 | 43 | 13 | 4-φ16 | 190 | 100 |

| 25 | 1 | 127 | 108 | 79.5 | 51 | 14.5 | 4-φ16 | 230 | 120 |

| 32 | 11/4 | 140 | 117 | 89 | 63.5 | 16 | 4-φ16 | 245 | 120 |

| 40 | 11/2 | 165 | 127 | 98.5 | 73 | 17.5 | 4-φ16 | 285 | 150 |

| 50 | 2 | 178 | 152 | 120.5 | 92 | 19.5 | 4-φ19 | 325 | 150 |

| 65 | 21/2 | 190 | 178 | 139.5 | 105 | 22.5 | 4-φ19 | 350 | 180 |

| 80 | 3 | 203 | 190 | 152.5 | 127 | 24 | 4-φ19 | 380 | 200 |

| 100 | 4 | 229 | 229 | 190.5 | 157 | 24 | 8-φ19 | 460 | 200 |

| 125 | 5 | 254 | 254 | 216 | 186 | 24 | 8-φ22 | 630 | 250 |

| 150 | 6 | 267 | 279 | 241.5 | 216 | 25.5 | 8-φ22 | 635 | 250 |

| 200 | 8 | 292 | 343 | 298.5 | 270 | 2 | 8-φ22 | 765 | 280 |

| 250 | 10 | 330 | 406 | 362 | 324 | 30.5 | 12-φ26 | 895 | 300 |

| 300 | 12 | 356 | 483 | 432 | 381 | 32 | 12-φ26 | 1080 | 350 |

| 350 | 14 | 381 | 533 | 476 | 413 | 35 | 12-φ29 | 1295 | 350 |

| 400 | 16 | 406 | 497 | 540 | 470 | 37 | 16-φ29 | 1435 | 400 |

| 450 | 18 | 432 | 635 | 578 | 533 | 40 | 16-φ32 | 1625 | 400 |

| 500 | 20 | 457 | 699 | 635 | 584 | 43 | 20-φ32 | 1830 | 450 |

| 600 | 24 | 508 | 813 | 749.5 | 692 | 48 | 20-φ35 | 2175 | 500 |

| 650 | 26 | 559 | 786 | 745 | 711 | 41.5 | 36-φ22 | 2235 | 550 |

| 700 | 28 | 610 | 837 | 795 | 762 | 44.5 | 40-φ22 | 2310 | 600 |

| 750 | 30 | 610 | 887 | 846 | 813 | 44.5 | 44-φ22 | 2695 | 600 |

| 800 | 32 | 660 | 941 | 900 | 864 | 46 | 48-φ22 | 3710 | - |

| 900 | 36 | 711 | 1057 | 1011 | 972 | 52.5 | 44-φ26 | 3925 | - |

| 1000 | 40 | 811 | 1175 | 1121 | 1080 | 56 | 44-φ29 | 4320 | - |