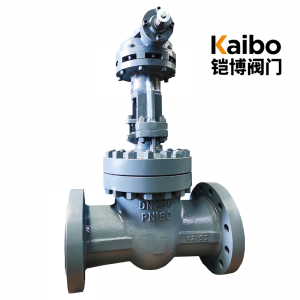

Electrical Gate Valve

| PN(MPa) | housing | Test pressure (Mpa) | Upper seal | |

| seal(liquid state) | seal(gas state) | |||

| 1.6 | 2.4 | 1.8 | 0.6 | 1.8 |

| 2.5 | 3.8 | 2.8 | 0.6 | 2.8 |

| 4.0 | 6.0 | 4.4 | 0.6 | 4.4 |

| 6.4 | 9.6 | 7.0 | 0.6 | 7.0 |

| 10.0 | 15.0 | 11.0 | 0.6 | 11.0 |

| 16.0 | 24.0 | 18.0 | 0.6 | 18.0 |

| Valve body, valve cover | Valve plate and seat | Stem | Stem nut | filler | handwheel |

| carbon steel | Excellent carbon steel + cemented carbide or stainless steel | Chromium stainless steel | Aluminum bronze | Graphite asbestos packing | malleable iron |

| Chromium nickel titanium steel | Stainless steel, stainless steel + cemented carbide | Chromium nickel titanium stainless steel | Aluminum bronze | teflon | malleable iron |

| Chromium nickel molybdenum titanium steel | Stainless steel, stainless steel + cemented carbide | Chromium nickel titanium stainless steel | Aluminum bronze | teflon | malleable iron |

| Chromium molybdenum steel | Alloy steel + cemented carbide | Chromium molybdenum steel | Aluminum bronze | Flexible asbestos | malleable iron |

| DN | L | D | D1 | D2 | b | Z-d | H | D0 |

| Z41H-16C | ||||||||

| 15 | 130 | 95 | 65 | 45 | 14-2 | 4-Φ14 | 170 | 120 |

| 20 | 150 | 105 | 75 | 55 | 14-2 | 4-Φ14 | 190 | 140 |

| 25 | 160 | 115 | 85 | 65 | 14-2 | 4-Φ14 | 205 | 160 |

| 32 | 180 | 135 | 100 | 78 | 16-2 | 4-Φ18 | 270 | 180 |

| 40 | 200 | 145 | 110 | 85 | 16-3 | 4-Φ18 | 310 | 200 |

| 50 | 250 | 160 | 125 | 100 | 16-3 | 4-Φ18 | 358 | 240 |

| 65 | 265 | 180 | 145 | 120 | 18-3 | 4-Φ18 | 373 | 240 |

| 80 | 280 | 195 | 160 | 135 | 20-3 | 8-Φ18 | 435 | 280 |

| 100 | 300 | 215 | 180 | 155 | 20-3 | 8-Φ18 | 500 | 300 |

| 125 | 325 | 245 | 210 | 185 | 22-3 | 8-Φ18 | 614 | 320 |

| 150 | 350 | 280 | 240 | 210 | 24-3 | 8-Φ23 | 674 | 360 |

| 200 | 400 | 335 | 295 | 265 | 26-3 | 12-Φ23 | 811 | 400 |

| 250 | 450 | 405 | 355 | 320 | 30-3 | 12-Φ25 | 969 | 450 |

| 300 | 500 | 460 | 410 | 375 | 30-3 | 12-Φ25 | 1145 | 580 |

| 350 | 550 | 520 | 470 | 435 | 34-4 | 16-Φ25 | 1280 | 640 |

| 400 | 600 | 580 | 525 | 485 | 36-4 | 16-Φ30 | 1452 | 640 |

| Z41H-25 | ||||||||

| 15 | 130 | 95 | 65 | 45 | 16-2 | 4-Φ14 | 170 | 120 |

| 20 | 150 | 105 | 75 | 55 | 16-2 | 4-Φ14 | 190 | 140 |

| 25 | 160 | 115 | 85 | 65 | 16-2 | 4-Φ14 | 205 | 160 |

| 32 | 180 | 135 | 100 | 78 | 18-2 | 4-Φ18 | 270 | 180 |

| 40 | 200 | 145 | 110 | 85 | 18-3 | 4-Φ18 | 310 | 200 |

| 50 | 250 | 160 | 125 | 100 | 20-3 | 4-Φ18 | 358 | 240 |

| 65 | 265 | 180 | 145 | 120 | 22-3 | 8-Φ18 | 373 | 240 |

| 80 | 280 | 195 | 160 | 135 | 22-3 | 8-Φ18 | 435 | 280 |

| 100 | 300 | 230 | 190 | 160 | 24-3 | 8-Φ23 | 500 | 300 |

| 125 | 325 | 270 | 220 | 188 | 28-3 | 8-Φ25 | 614 | 320 |

| 150 | 350 | 300 | 250 | 218 | 30-3 | 8-Φ25 | 674 | 360 |

| 200 | 400 | 360 | 310 | 278 | 34-3 | 12-Φ25 | 811 | 400 |

| 250 | 450 | 425 | 370 | 332 | 36-3 | 12-Φ30 | 969 | 450 |

| 300 | 500 | 485 | 430 | 390 | 40-4 | 16-Φ30 | 1145 | 580 |

| 350 | 550 | 550 | 490 | 448 | 44-4 | 16-Φ34 | 1280 | 640 |

| 400 | 600 | 610 | 550 | 505 | 48-4 | 16-Φ34 | 1452 | 640 |

Write your message here and send it to us