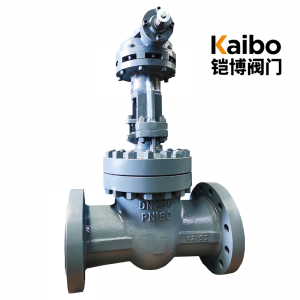

High Pressure Flanged Gate Valve

| Design and Manufacture | Face To Face | Flange Dimension | Pressure Temperature Lating | spection And Test |

| GB122234 | GB12221 | GB9113 JB79 | GB9131 | GB/T13927 JB/T9092 |

| Body Cover Disc | Stem | Sealing Face | Sealing Shim | Packing | Working Temperature | Suitable Medium |

| WCB | 2Cr13 | 13Cr STL With Body Material Nylon |

Enhanced Flexible Graphite 1Cr13/Flexible Graphite 08 Soft Steal |

Flexible Graphite Enhanced Flexible Graphite SFB/260 SFP/260 PTFE |

≤425 | Water Steam Oil Goods |

| WC1 | 38CrMoAl 25Cr2MoV |

≤450 | ||||

| WC6 | ≤540 | |||||

| WC9 | ≤570 | |||||

| C5 C12 | ≤540 | |||||

| ZGCr5Mo | ≤200 | Nitric acid | ||||

| ZG1Cr18Ni9Ti | 1Cr18Ni9Ti | |||||

| ZG1Cr18Ni12Mo2Ti | 1Cr18Ni12Mo2Ti | Acetic acid |

| Nominal Pressure | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

| Shell Test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | 24.0 |

| Water Seal Test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 18.0 |

| Backseat Test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 18.0 |

| Air Seal Test | 0.4-0.7 | |||||

| 1.6MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 | |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 | |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 | |

| 2.5MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 | |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 | |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 | |

| 4.0MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |||

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 280 | 310 | 350 | 400 | 450 | 550 | 650 | 750 | 850 | 950 | ||||

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | ||||

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | ||||

| 6.4MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |||

| L | mm | 170 | 190 | 210 | 230 | 240 | 250 | 280 | 320 | 350 | 400 | 450 | 550 | 650 | 750 | 850 | 950 | ||||

| H | mm | 175 | 180 | 210 | 230 | 350 | 359 | 373 | 435 | 500 | 614 | 674 | 818 | 970 | 1145 | 1280 | 1450 | ||||

| W | mm | 120 | 120 | 140 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 400 | 450 | 560 | 640 | 800 | 800 | ||||

| 10.0MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | ||||||

| L | mm | 170 | 190 | 210 | 230 | 240 | 250 | 280 | 310 | 350 | 400 | 450 | 550 | 650 | |||||||

| H | mm | 175 | 180 | 210 | 230 | 350 | 359 | 373 | 435 | 500 | 614 | 674 | 818 | 970 | |||||||

| W | mm | 120 | 120 | 160 | 180 | 240 | 280 | 320 | 360 | 400 | 450 | 560 | 640 | 720 | |||||||

| 16.0MPa | size | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |||||||

| L | mm | 170 | 190 | 210 | 230 | 240 | 300 | 340 | 390 | 450 | 525 | 600 | 750 | ||||||||

| H | mm | 175 | 180 | 210 | 230 | 350 | 359 | 373 | 435 | 500 | 614 | 674 | 818 | ||||||||

| W | mm | 120 | 120 | 140 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 400 | 450 |

Write your message here and send it to us