Dual Plate Check Valve - Manufacturers, Suppliers, Factory from China

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for Dual Plate Check Valve, Boiler Non Return Valve, Non Return Valve, Air Foot Valve,Different Types Of Check Valves. Always for the majority of business users and traders to provide best quality products and excellent service. Warmly welcome to join us, let's innovation together, to flying dream. The product will supply to all over the world, such as Europe, America, Australia,Washington, Plymouth,Dubai, Ukraine.After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

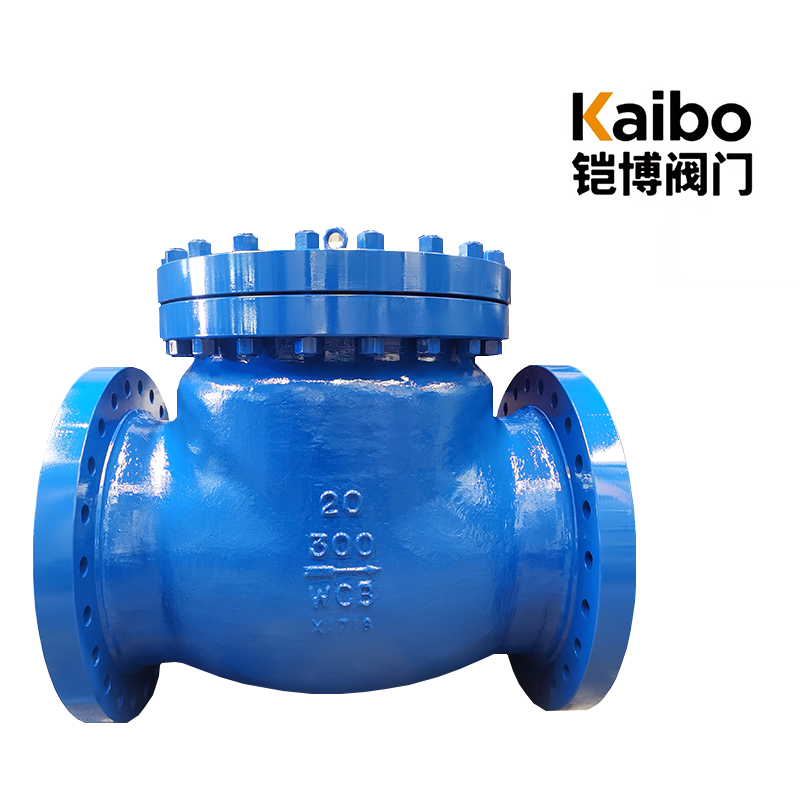

Related Products